- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Languages

Views: 1768 Author: Site Editor Publish Time: 2026-02-03 Origin: Site

Content Menu

● Common Clay Usage Errors & Surface Damage Prevention: FMEA Approach | BrilliaChem

>> Professional Insights from BrilliaChem (SGS, ISO & BSCI Certified Manufacturer)

● 1. Understanding Clay Bar Risks

● 2. Common Clay Bar Usage Errors

>> 2.2 Applying Excessive Pressure

>> 2.3 Reusing Contaminated Clay

>> 2.4 Ignoring Surface Lubrication

>> 2.5 Using Incorrect Clay Type

● 3. FMEA-Based Approach to Clay Bar Surface Safety

● 4. BrilliaChem’s Quality Control Measures

● 5. Best Practices for Safe Clay Bar Application

● 6. FAQ – Frequently Asked Questions

>> Q1: How often should clay bars be replaced?

>> Q2: Can I use clay bars on all paint types?

>> Q3: Does using more lubricant reduce surface scratches?

>> Q4: Can folding the clay repeatedly prevent damage?

>> Q5: How does BrilliaChem ensure clay bar quality?

Clay bars are a cornerstone of automotive detailing, widely used to remove contaminants, overspray, and industrial fallout from painted surfaces. While they are highly effective, improper usage can lead to surface damage, scratches, or uneven finish, creating issues for both professionals and car enthusiasts.

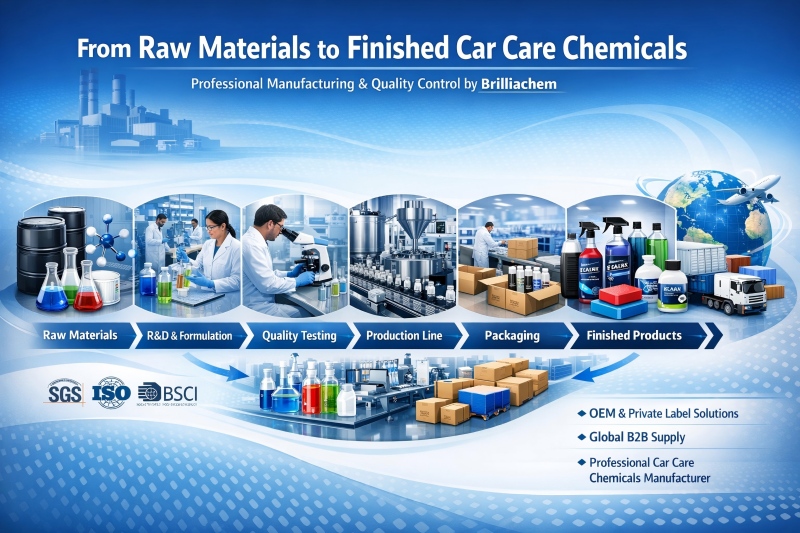

This article examines common clay bar usage errors and introduces an FMEA-based (Failure Mode and Effects Analysis) approach to prevent surface damage. Written from the perspective of BrilliaChem, an SGS, ISO, and BSCI certified clay bar manufacturer, this guide is designed for detailing professionals, global buyers, and car care brand operators who want to optimize both safety and performance in clay bar application.

Clay bars work by gently abrading contaminants on the vehicle’s paint surface. While effective, risks include:

Swirl marks and micro-scratches

Paint hazing or dulling

Embedded clay debris causing damage

Contamination of clay bar during storage

Using clay on inappropriate surfaces

Even high-quality clay bars from certified manufacturers like BrilliaChem require proper technique to prevent these failures.

Problem: Dry clay grips the surface, increasing abrasion risk.

Effect: Surface scratches, paint removal

Prevention: Always lubricate with detailing spray or quick detailer.

Problem: Forceful rubbing may embed contaminants or cut into paint.

Effect: Visible scratches, swirl marks

Prevention: Use light, consistent pressure, letting the clay glide naturally.

Problem: Clay picks up metal, brake dust, and grime during use.

Effect: Scratching the same or adjacent panels

Prevention: Fold clay frequently to expose a clean surface; replace when heavily contaminated.

Problem: Lack of lubrication increases friction.

Effect: Micro-marring, surface haze

Prevention: Always spray generous amounts of clay lubricant.

Problem: Medium or heavy clay on delicate paints may damage surface.

Effect: Paint removal or swirl marks

Prevention: Choose fine-grade clay for sensitive surfaces; reserve medium for heavily contaminated areas.

Problem: Clay exposed to dirt or extreme temperatures.

Effect: Hardened clay, reduced effectiveness

Prevention: Store in airtight containers; keep away from heat or direct sunlight.

FMEA (Failure Mode and Effects Analysis) is a structured method for identifying potential failure modes in processes and assessing their impact. Applied to clay bar usage:

| Failure Mode | Effect | Cause | Severity (1–10) | Detection | Preventive Action |

|---|---|---|---|---|---|

| Dry clay usage | Surface scratches | Lack of lubrication | 8 | 7 | Always use detail spray or quick detailer |

| Excessive pressure | Paint marring | Operator technique | 9 | 6 | Training & instruction videos |

| Contaminated clay | Embedded scratches | Reuse without folding | 9 | 8 | Fold clay, replace if contaminated |

| Wrong clay grade | Paint dulling | Inappropriate clay type | 7 | 6 | Use recommended grade per surface |

| Improper storage | Hardened clay | Exposure to dust or heat | 6 | 7 | Airtight container, controlled temperature |

Benefits of FMEA:

Predicts potential failure points

Reduces surface damage risk

Provides systematic preventive measures

Improves customer satisfaction

BrilliaChem ensures all clay bars meet international quality standards, including:

SGS testing for chemical safety and material stability

ISO 9001 quality management system

BSCI social compliance

Controlled hardness, elasticity, and contamination resistance

Packaging that preserves clay integrity during storage and transport

Professional buyers and detailers can rely on BrilliaChem clay bars for consistent performance and minimal surface risk.

Pre-wash and rinse car surface to remove loose debris

Use dedicated clay lubricant or quick detailer

Light pressure: let the clay glide across the surface

Check clay cleanliness regularly; fold or replace when dirty

Avoid using clay on unpainted plastic or rubber surfaces

Work in small sections to maintain lubrication and control

Finish with polish or sealant after claying for optimal results

A: When they are heavily contaminated, hardened, or no longer glide smoothly.

A: Fine-grade clay is safe for all automotive paints. Medium or heavy clay is for stubborn contaminants only.

A: Yes. Adequate lubrication minimizes friction and reduces marring risk.

A: Yes. Folding exposes a clean surface, preventing embedded particles from scratching paint.

A: Through SGS testing, ISO quality management, BSCI compliance, and controlled production processes.

Preventing surface damage while using clay bars requires knowledge, technique, and high-quality materials. Applying an FMEA-based approach helps professionals and enthusiasts identify risk points and implement preventive measures effectively.

By choosing BrilliaChem clay bars, buyers benefit from:

Certified quality (SGS, ISO, BSCI)

Consistent clay performance

Reduced risk of surface scratches

Detailed usage guidance and support

Proper usage combined with professional-grade clay bars ensures vehicles achieve flawless finishes while protecting painted surfaces from common mistakes.