- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Languages

Views: 532 Author: Site Editor Publish Time: 2025-12-01 Origin: Site

Content Menu

● Behind the Scenes: How We Produce 10 Million Clay Bars a Year

● Step 1 — Raw Material Selection (Where Quality Begins)

● Step 2 — Precision Mixing for Consistent Grade Performance

>> Fine Grade (Soft / Safe for Maintenance Clay)

>> Medium Grade (Most Popular / Professional Use)

>> Heavy Grade (Aggressive / Industrial Use)

● Step 3 — High-Capacity Extrusion & Molding

● Step 4 — Strict Quality Control (SGS-Level Standards)

● Step 5 — Custom Branding, Packaging & Private Label Services

● Step 6 — Global Export & OEM Support

● Why Leading Car Care Brands Trust Brilliachem

>> ✔ China’s largest clay bar factory

>> ✔ Massive production capacity + stable supply

>> ✔ Professional R&D team under Carwashcn

● Ready to Create Your Own Clay Bar Brand?

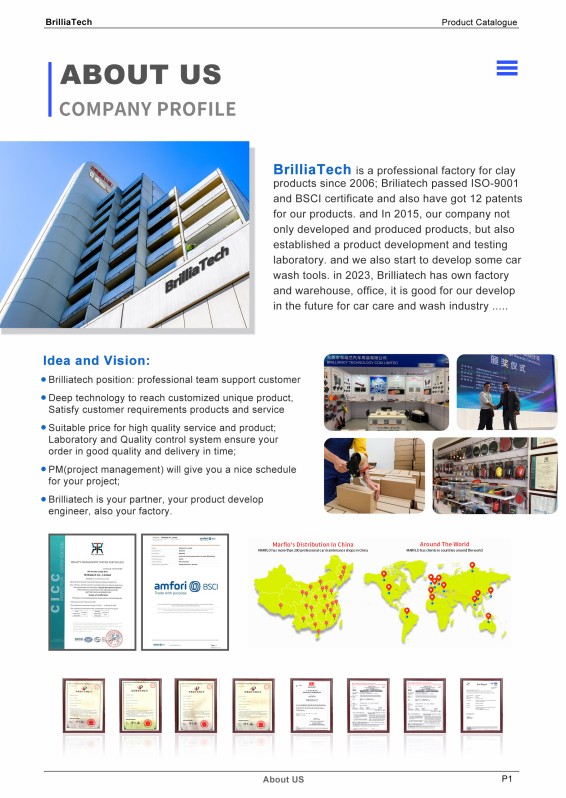

As one of the world’s largest clay bar manufacturers, Brilliachem produces over 10 million clay bars every year for global detailing brands, wholesalers, and car wash chains. With SGS, ISO and BSCI–certified facilities, and an independent R&D department under Carwashcn, we provide high-quality, customizable clay bars trusted by professionals in over 60+ countries.

This article takes you behind the scenes to reveal how a premium clay bar is made, how we maintain consistent quality at massive scale, and why so many brands choose to manufacture with us.

A high-performance clay bar starts with ultra-clean synthetic resin + elastic polymer binders.

At Brilliachem, every raw ingredient must pass:

Purity inspection (≥99%)

Elasticity test

Temperature stability test

Contamination-free lab screening

This ensures every clay bar performs well on clear coat, chrome, glass, and metal without scratching.

Our mixing engineers calibrate formulas according to the grade you need:

For removing light contamination, suitable for mobile detailers and weekly washes.

Balances aggressiveness and safety. Cleans fallout, overspray, heavy dirt.

For extreme contamination, widely used by repainting shops and heavy-duty detailing.

Each batch is mixed in temperature-controlled reactors to ensure uniform texture and elasticity.

Our automated production lines are designed to meet global orders of any size:

Daily output: 28,000–35,000 clay bars

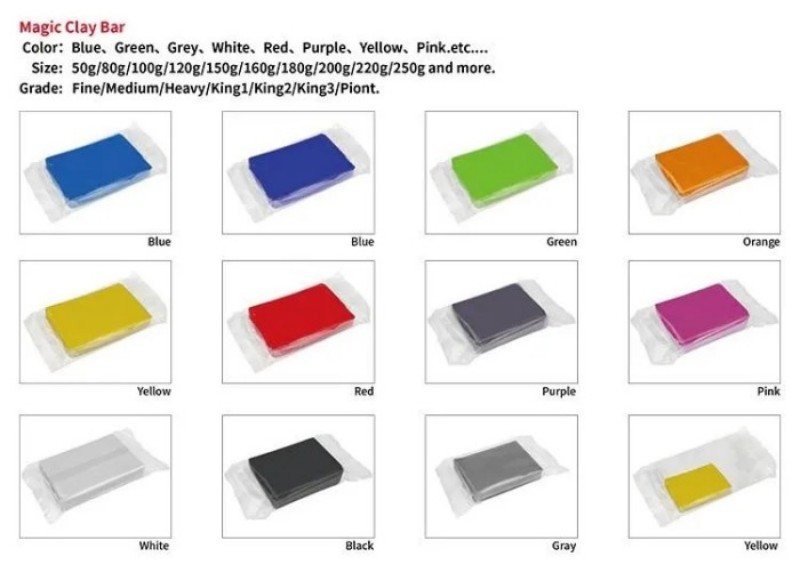

Custom sizes: 50g / 100g / 150g / 200g

Custom shapes: rectangular, round, brick-style

Custom colors: blue, purple, yellow, gray, black

We use precision extrusion machines to guarantee:

Uniform thickness

High density

Zero air pockets

Stable elasticity

This is how we maintain consistency even at 10 million units per year.

Every clay bar goes through 6 layers of inspection:

Visual surface inspection

Elasticity stretch test (≥ 300%)

Contaminant detection

Hardness test

High-temp stability test

Paint panel scratch test

Our QC team ensures each clay bar is safe for all automotive surfaces before packaging.

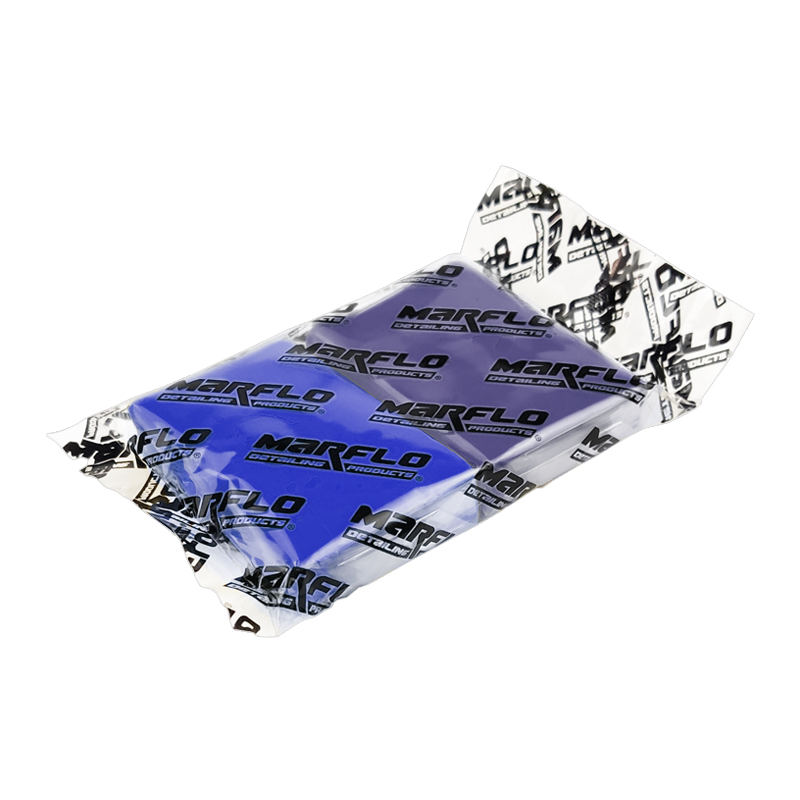

Brilliachem is known for one-stop private label production:

Custom logo clay bar

Custom packaging (box, bag, tin case)

Custom color & grade

Custom scent (optional)

Custom barcode & FNSKU

Custom instruction manuals

Our Carwashcn independent development department helps distributors and car wash chains build a strong brand with:

Fast sample service

Exclusive formulas

Market-ready designs

Dropshipping support

We assist newly launched brands as well as large global chains.

We ship to more than 60+ countries, especially:

USA

Germany

UK

Brazil

Mexico

Australia

All products follow SGS, ISO, BSCI export standards.

One of the few manufacturers capable of producing 10,000,000+ units annually.

From formula → production → branding → global shipping.

SGS, ISO, BSCI approved.

Brilliachem provides complete OEM/ODM support for:

Detailing brands

Auto wash chains

Distributors

Online sellers (Amazon / eBay / Shopify)

Whether you need private label clay bars, a full clay bar kit, or want to scale your brand, our factory can support your growth.